Introduction to Heat Transfer vs Screen Printing

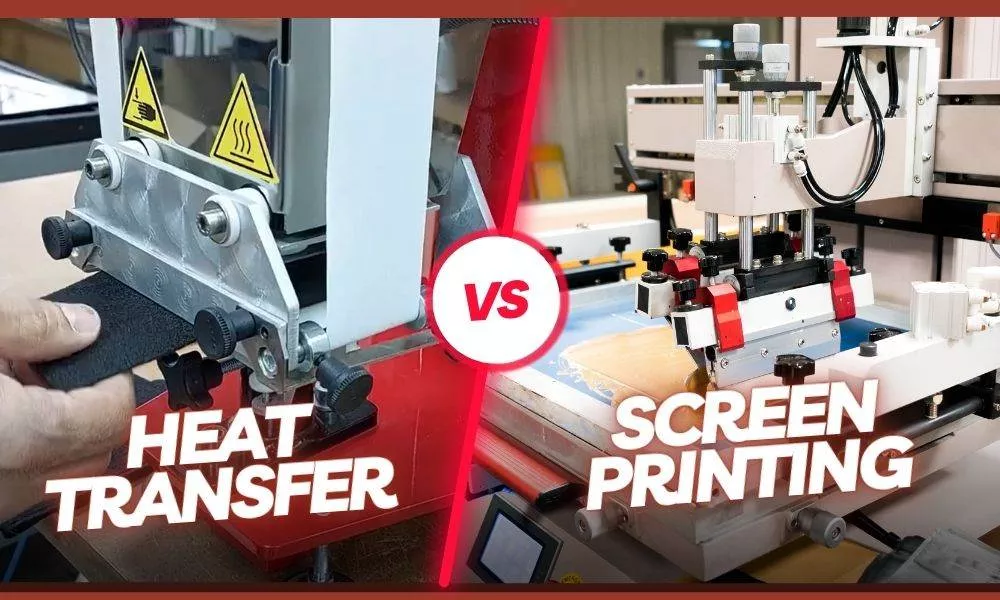

When it comes to customizing garments, two popular methods stand out: heat transfer and screen printing. Both techniques have their advantages and drawbacks, making it essential to understand their differences to make an informed decision. In this article, we will explore the processes, pros, and cons of screen printing and heat transfer, and compare them in various aspects to determine which method, heat transfer vs screen printing, is better suited for different needs.

What is Heat Transfer Printing

Heat transfer, also known as heat press printing, is a modern printing method that utilizes heat and pressure to transfer a design onto fabric. It involves using a heat press machine to apply heat and pressure, causing the design to adhere to the garment. Heat transfer is popular for its versatility and ease of use.

Process and Techniques Heat Transfer Printing

Heat transfer involves printing the design onto a special heat transfer paper using a standard printer or a specialized inkjet printer. The design is then placed on the fabric, and heat and pressure are applied using a heat press machine, which bonds the design onto the garment.

Pros and Cons Heat Transfer Printing

Heat transfer provides flexibility and the ability to produce intricate designs without the need for multiple screens. It is suitable for small quantities, quick turnarounds, and designs with gradients or photographs. However, it may not be as durable as screen printing, especially when exposed to frequent washing or harsh conditions.

Pros:

- Speedy & Efficient: Say goodbye to lengthy setups and elaborate processes. Heat transfer printing is a breeze, delivering quick turnaround times, perfect for last-minute projects or small batch orders.

- Material Magic: Unlike some picky printing methods, heat transfer embraces diversity. From polyester to cotton and even canvas, it seamlessly bonds with a wide range of fabrics, opening up a world of creative possibilities.

- Color Explosion: Vibrant hues and intricate details? Heat transfer delivers! Its ability to capture bold colors and intricate designs makes it ideal for eye-catching graphics and logos.

- Budget-Friendly (Initially): Compared to other printing methods like screen printing, heat transfer can be a steal, especially for small projects. No heavy machinery or complex setup – just a simple press and you’re good to go.

- Minimal Mess: Forget messy inks and dyes. Heat transfer keeps things clean and contained, making it a hassle-free option for both beginners and seasoned pros.

Cons:

- Durability Dilemma: While convenient, heat transfer’s Achilles’ heel lies in its longevity. The bond between ink and fabric can be delicate, prone to cracking and fading over time, especially with frequent washing and drying.

- Design Limitations: Freedom of expression takes a backseat with heat transfer. Most designs are pre-made or require specific file formats, limiting customization options.

- Environmental Concerns: Not all heat transfer methods are created equal. Some traditional transfer papers contain harmful chemicals that raise environmental and health concerns.

- Setup Costs: While initially cheaper for small orders, heat transfer requires an upfront investment in transfer paper or pre-made transfers. This cost can outweigh the initial savings for larger projects.

- Wash & Wear Worries: Delicate fabrics and high-wash garments might not be the best partners for heat transfer. Special care and specific washing instructions are often necessary to maintain the print’s integrity.

Here’s a video to show how heat transfer prints on a T-shirt:

What is Screen Printing

Screen printing is a traditional and widely-used method of printing designs on various materials. The process involves creating a stencil (screen) of the desired design and applying ink through it onto the fabric. Screen printing offers exceptional durability and vibrant colors, making it ideal for large-scale production and designs that require a high level of detail.

Process and Techniques Screen Printing

Screen printing begins with preparing the design and transferring it onto a mesh screen. The areas not meant to be printed are blocked using a stencil. Ink is then applied to the screen, which is pressed onto the fabric, allowing the ink to pass through the open areas of the stencil.

Pros and Cons Screen Printing

Screen printing offers excellent color vibrancy, durability, and longevity. It can be used on various materials and is suitable for large quantities. However, it requires specialized equipment, setup time, and may not be cost-effective for small batches or designs with intricate details.

Pros:

- Durability Champion: Forget fleeting designs! Screen printing boasts unparalleled durability, bonding ink deep within the fabric’s fibers. Your designs withstand countless washes and wear, staying vibrant and bold for years to come.

- Versatility King: From cotton to canvas, denim to polyester, screen printing embraces a diverse kingdom of fabrics. This flexibility makes it ideal for a wide range of projects, from T-shirts and tote bags to home décor and even industrial applications.

- Color Maestro: Craving a rainbow explosion on your garment? Screen printing delivers! It handles a vast spectrum of colors, from delicate pastels to eye-searing neons, creating stunningly vibrant and intricate designs.

- Customization Champion: Unlike the cookie-cutter world of heat transfer, screen printing lets your creativity run wild. From custom designs to intricate textures, the possibilities are endless, allowing you to truly personalize your creations.

Cons:

- Speedy Setup? Not Quite: Screen printing setup involves a more involved process, with screens, inks, and equipment requiring preparation. This can be time-consuming, especially for beginners or small projects.

- Cost Considerations: While cost-effective for large orders, screen printing can be expensive for smaller batches due to the setup costs. Factor in screen preparation, ink usage, and potential equipment investment.

- Complexity Curve: Screen printing has a learning curve. Mastering the technique requires practice and understanding of ink types, screen mesh, and printing methods.

- Limited Material Options: While versatile, some delicate fabrics might not be suitable for screen printing due to the pressure and potential for damage.

- Artwork Restrictions: Complex, multi-color designs might require multiple screens, adding to setup time and cost. Consider the level of detail and number of colors before diving in.

Heat Transfer vs Screen Printing Comparison

Quality and Durability

Screen printing generally offers superior quality and durability compared to heat transfer. The ink used in screen printing penetrates the fabric, resulting in vibrant, long-lasting designs. Heat transfer, on the other hand, can fade or peel over time, particularly with frequent washing.

Imagine your design as a tattoo. Screen printing is like the needle, meticulously embedding ink into the fabric’s very essence. Heat transfer, on the other hand, is a mere sticker, clinging precariously to the surface. This difference in depth translates to endurance. Wash after wash, your screen-printed design stays true, while the heat transfer’s grip eventually weakens, cracking and fading like a weathered decal.

This happens because Screen printing infuses the fabric with ink, creating a permanent bond that transcends mere surface adhesion.

Cost and Versatility

When it comes to cost, heat transfer is more suitable for small quantities or single-piece orders, as it doesn’t require significant setup costs or specialized equipment. Screen printing becomes more cost-effective for larger quantities. In terms of versatility, heat transfer allows for intricate designs, gradients, and photographic prints, while screen printing is better suited for solid colors and bold designs.

Design Complexity

Heat transfer excels in handling intricate designs, gradients, and photographic prints due to its ability to reproduce fine details accurately. Screen printing, on the other hand, is better suited for designs with solid colors and fewer color variations.

Production Speed

Heat transfer offers faster production times compared to screen printing. With heat transfer, designs can be printed and applied to garments relatively quickly, making it an ideal choice for tight deadlines or last-minute orders. Screen printing involves more setup time, including creating screens and aligning colors, which can slow down the production process.

Here is a comparison table of heat transfer and screen printing:

| Feature | Heat Transfer | Screen Printing |

| Durability | Less durable | More durable |

| Cost | More expensive for small orders, less expensive for large orders | Less expensive for small orders, more expensive for large orders |

| Complexity of design | Can handle complex designs | Best for simple designs |

| Number of colors | Can handle multiple colors | Best for single-color designs |

| Time to produce | Faster | Slower |

| Materials | Heat transfer vinyl, heat press | Screens, inks, squeegees |

| Applications | T-shirts, hats, bags, and other garments | T-shirts, hats, bags, other garments |

Heat Transfer vs Screen Printing Which is Better?

Selecting the appropriate printing method depends on several factors. For large-scale productions, designs with solid colors, and a focus on durability, screen printing is often the preferred choice. On the other hand, heat transfer is suitable for smaller quantities, intricate designs, quick turnarounds, and designs that require gradients or photographic elements.

Consider factors such as budget, design complexity, production speed, and the desired level of durability when making a decision. It’s also beneficial to consult with printing professionals who can provide guidance based on your specific requirements.

When it comes to heat transfer printing, INNOTRANSFERS stands out as a leading company specializing in the design and production of high-quality heat transfer prints for the textile industry. As a prominent European business group, we pride ourselves on being manufacturers of top-notch textile transfers and innovative textile transfer printing technology. Our heat transfer prints boast exceptional quality and durability, making them perfect for various applications in the textile industry. Whether you need intricate designs or vibrant gradients, our heat transfer prints can bring your vision to life with precision and vibrant colors. With our quick turnaround times and commitment to excellence, INNOTRANSFERS is your go-to choice for superior heat transfer printing solutions.

Conclusion

Screen printing and heat transfer both offer unique advantages in garment customization. Screen printing provides exceptional durability, and vibrant colors, and is cost-effective for large quantities, while heat transfer offers versatility, quick turnarounds, and the ability to reproduce intricate designs. Ultimately, the choice between the two methods depends on the specific needs and priorities of each project.

By understanding the processes, pros, and cons of screen printing and heat transfer, you can make an informed decision to achieve the desired results for your custom garment printing needs.

FAQs

Which printing method is more cost-effective for small orders?

Heat transfer is generally more cost-effective for small quantities or single-piece orders due to its minimal setup costs.

Can screen printing reproduce photographic prints?

While screen printing can produce high-quality designs, it is not as suitable for reproducing intricate photographic prints as heat transfer.

Do you need a heat press for screen printing?

No, a heat press is not needed for screen printing; it requires a screen, ink, and squeegee for the printing process.

what is heat press printing?

Heat press printing is a method that uses heat and pressure to transfer designs onto various materials, such as fabric or ceramics, resulting in vibrant and long-lasting customizations.

My company’s giving away free graphic tees with awesome designs of our brand and logo as some sort of marketing strategy to introduce our company to everyone. I’ll tell my boss that excellent color vibrancy, durability, and lifespan are all features of screen printing. As you said, it is appropriate for big volumes and may be used on a variety of materials. We needed this.

Please feel free to contact us

Wow, this article really clarified the differences between heat transfer and screen printing! I’ve been contemplating starting a screen print program for my small business, and this information is invaluable. The insight into the durability of screen printing over time, especially with frequent washing, is exactly what I needed to know. Can anyone recommend good screenprint software to get started? Thanks in advance for any suggestions!

Thank you so much for the feedback! We are really glad to hear our article helped explain the key differences between heat transfer and screen printing. Ensuring readers like yourself have the information they need to make informed decisions for their business is our top priority.

Great comparison! I appreciate the clear breakdown of heat transfer and screen printing. It helps me make a more informed decision for my upcoming project.

Thank you so much for the feedback!