In a world increasingly focused on sustainability, the textile industry is undergoing a transformation to minimize its ecological footprint. Eco-friendly textile printing is an essential aspect of this transition, offering environmentally conscious alternatives to traditional printing methods. This article delves into the concept of eco-friendly textile printing, explores sustainable textile printing techniques, highlights innovative solutions, and discusses the advantages and challenges associated with this growing trend.

Understanding Eco-Friendly Textile Printing

The Importance of Sustainable Practices

Sustainability has become a key concern across industries, including textiles. Textile production is believed to contribute to approximately 20% (Source-European Parliament) of worldwide water pollution caused by the dyeing and finishing processes. As consumers become more aware of the environmental impact of their choices, there is a rising demand for sustainable and eco-friendly Textile printing, which has traditionally relied on chemical-intensive processes, is now adapting to meet these demands.

Harmful Effects of Traditional Textile Printing

Traditional textile printing involves various hazardous chemicals, such as formaldehyde, heavy metals, and volatile organic compounds (VOCs). These substances are harmful to both the environment and human health. Moreover, conventional printing methods often consume excessive amounts of water, contributing to water scarcity issues.

Advantages of Eco-Friendly Textile Printing

Eco-friendly textile printing offers several advantages over conventional methods. It reduces water consumption, minimizes the release of toxic chemicals, and decreases energy usage. By adopting sustainable techniques, textile manufacturers can enhance their brand image, attract eco-conscious consumers, and contribute to a greener future.

Eco-Friendly Textile Printing Techniques

Digital Printing

Digital printing is an eco-friendly alternative that uses inkjet technology to apply designs directly onto fabrics. It eliminates the need for screens, reduces water consumption, and allows for intricate patterns without excessive wastage of inks.

Pigment Printing

Pigment printing involves applying pigments to the fabric surface using a binder. This technique requires minimal water usage and has a lower impact on the environment compared to traditional methods. Pigment inks also offer excellent color fastness.

Natural Dyeing

Natural dyeing utilizes plant-based dyes extracted from renewable sources such as flowers, leaves, and roots. It offers a sustainable alternative to synthetic dyes while providing unique color variations and reducing water pollution.

Waterless Printing

Waterless printing eliminates the need for water by utilizing specialized inks and transfer processes. This technique reduces water consumption, energy usage, and wastewater generation, making it highly sustainable.

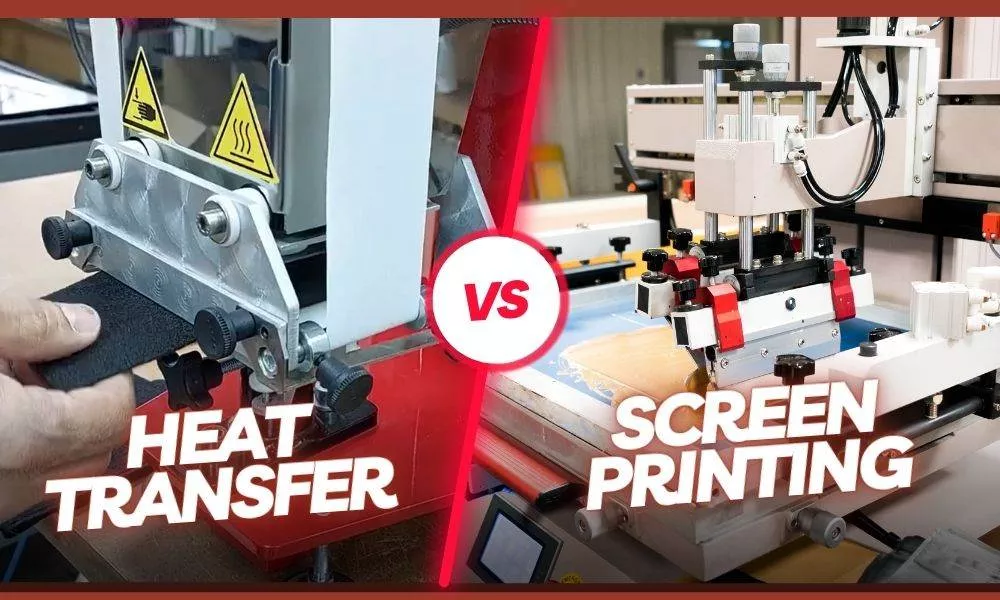

Heat Transfer Printing

Heat transfer printing involves using heat to transfer designs from paper to fabric. It requires fewer chemicals and has a minimal environmental impact. Heat transfer is particularly suitable for small-scale production or customization. Check out Innotransfers ECO-RESIST Heat transfers with totally ECO-Friendly inks, which resist industrial washing and are extremely flexible. These single-color transfers are especially recommended for hospital clothing, underwear, laundry textiles, and textile products that have to withstand washing and drying processes at very extreme temperatures. Innotransfers have been approved according to Oeko Tex Standard 100, which is the maximum quality level, and allow our transfers to be used on baby clothing and organic clothing. Offer a 100% Eco-Friendly product with Innotransfers!

Eco-Friendly Printing Inks and Dyes

Water-Based Inks

Water-based inks are made primarily from water, with lower levels of volatile organic compounds. They are considered environmentally friendly and provide excellent color vibrancy and durability.

Plant-Based and Natural Dyes

Plant-based and natural dyes are derived from renewable sources such as vegetables, fruits, and spices. They offer a sustainable alternative to synthetic dyes while providing a range of beautiful and unique color options.

Recycled Inks

Recycled inks are produced from post-consumer waste materials. By utilizing recycled ink cartridges, textile printers can contribute to waste reduction and support a circular economy.

Innovations in Eco-Friendly Textile Printing

Nanotechnology in Eco-Friendly Textile Printing

Nanotechnology has introduced innovative solutions in textile printing, such as self-cleaning fabrics, UV protection, and enhanced durability. These advancements contribute to the sustainability and longevity of textile products.

3D Printing for Sustainable Fashion

3D printing allows for precise and customized production, reducing material waste and energy consumption. It enables designers to create intricate patterns and textures while minimizing the environmental impact.

Biodegradable and Compostable Materials

The development of biodegradable and compostable materials opens new possibilities for sustainable textile printing. These materials, derived from natural sources, reduce the reliance on synthetic fibers and contribute to a circular economy.

Advantages and Challenges of Eco-Friendly Textile Printing

Reduced Environmental Impact

Eco-friendly textile printing techniques significantly reduce water consumption, energy usage, and the release of toxic chemicals into the environment. They help preserve water resources, reduce pollution, and mitigate climate change.

Improved Worker Safety

By minimizing the use of harmful chemicals, eco-friendly printing methods create safer working conditions for textile industry workers. This contributes to better health and well-being for employees in the manufacturing process.

Cost Considerations and Market Demand

While eco-friendly textile printing may have higher upfront costs, the growing demand for sustainable products presents significant market opportunities. Consumers are increasingly willing to pay a premium for eco-conscious brands, making sustainability a competitive advantage.

Technological Limitations

Despite the progress in eco-friendly printing techniques, there are still technological limitations that need to be addressed. These include limited color options, slower production speeds, and challenges in achieving certain effects or textures.

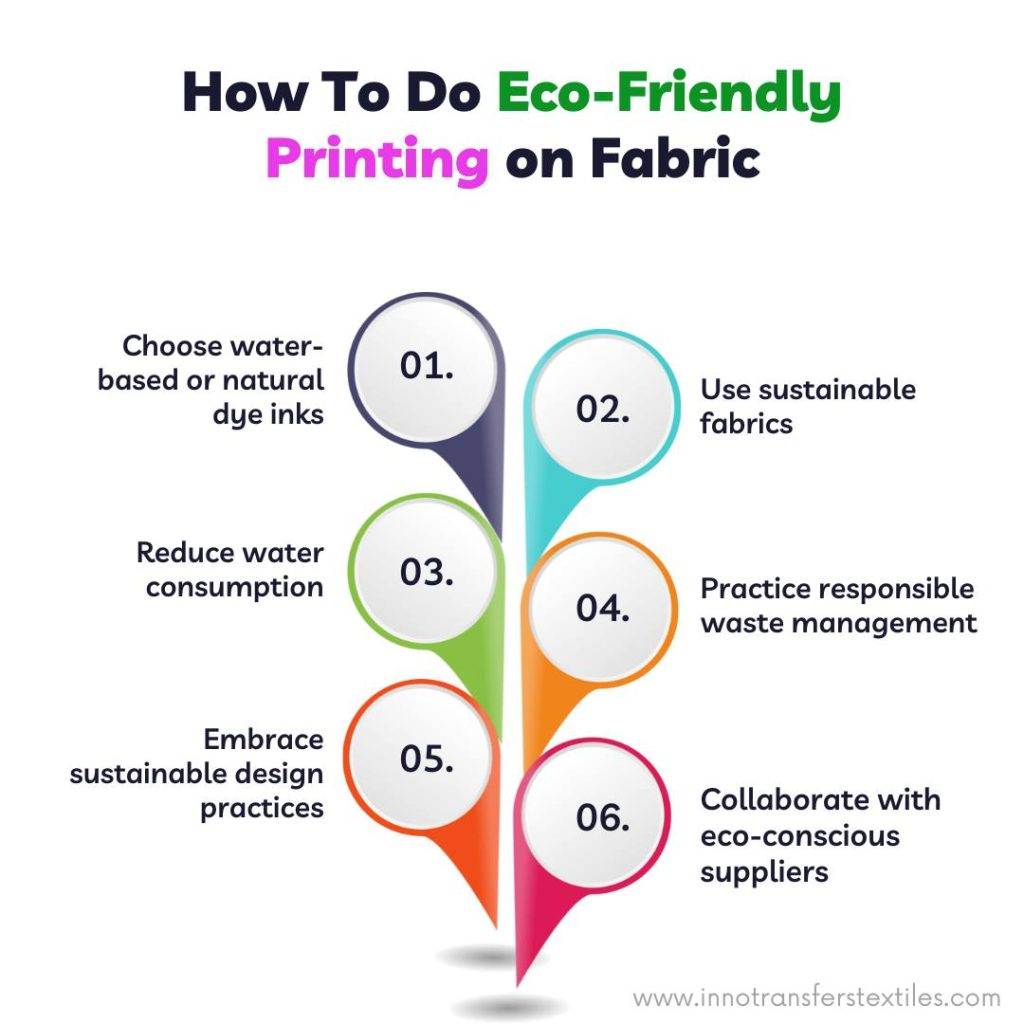

How To Do eco-Friendly Printing on Fabric

Choose water-based or natural dye inks: Opt for water-based inks that are free from harmful chemicals and have a lower impact on the environment. Alternatively, explore natural dyes extracted from plants or other renewable sources.

Use sustainable fabrics: Select fabrics made from organic or sustainable materials, such as organic cotton, bamboo, or hemp. These materials have a lower ecological footprint and are better for the environment.

Reduce water consumption: Minimize water usage by exploring printing techniques that require less water, such as digital printing or pigment printing. Consider using waterless printing methods whenever possible.

Practice responsible waste management: Properly dispose of printing waste and recycle materials whenever feasible. Implement recycling programs for screens, ink cartridges, and other printing supplies.

Embrace sustainable design practices: Incorporate sustainable design principles, such as minimizing ink usage, optimizing pattern layouts to reduce fabric waste, and considering the end-of-life recyclability of the printed fabric.

Collaborate with eco-conscious suppliers: Work with suppliers who prioritize eco-friendly practices and offer sustainable printing options. This ensures a holistic approach to eco-friendly printing.

Conclusion

Eco-friendly textile printing is a significant step towards a more sustainable and environmentally conscious fashion industry. By adopting innovative techniques, utilizing eco-friendly inks and dyes, and embracing new technologies, the textile industry can reduce its ecological footprint. Consumers also have a vital role to play by choosing sustainable products and supporting brands committed to eco-friendly practices. Together, we can create a greener future for the world of fashion.

FAQs

Is eco-friendly textile printing more expensive than traditional printing methods?

Eco-friendly textile printing may have higher upfront costs due to the use of specialized equipment and sustainable materials. However, the market demand for sustainable products is growing, which presents opportunities for brands to recoup these costs and establish a competitive edge.

Are the color options limited in eco-friendly textile printing?

While there may be some limitations in achieving certain colors with natural dyes or water-based inks, technological advancements continue to expand the range of colors available in eco-friendly textile printing.

How can consumers contribute to sustainable textile printing?

Consumers can contribute to sustainable textile printing by choosing eco-friendly brands, supporting circular economy initiatives, and educating themselves about the environmental impact of their purchasing decisions.

Is screen printing eco friendly?

Yes, screen printing can be eco-friendly when using water-based inks and implementing sustainable practices such as proper waste management and responsible substrate choices.

Baby world! nice post , thanks for this post.

Thanks